The current issue of the journal GyártásTrend is dealing with technologies and trends which may shape and transform the world of metalworking in the future in a thematic supplement. Such compilation must definitely include a company whose motto contains the expressions ’Flexibility – Innovation – Sheet metal’ – i.e. FlexInSheet Kft! András Szabó, our managing director has introduced the readers to the mysteries of the technology based on the bending of thin sheet metals, highlighting the advantages and potentials of the solution in the article published on the front page of the magazine. In the current post of our Blog we are attempting to briefly summarise the professional details.

What is the key to thin sheet metal processing?

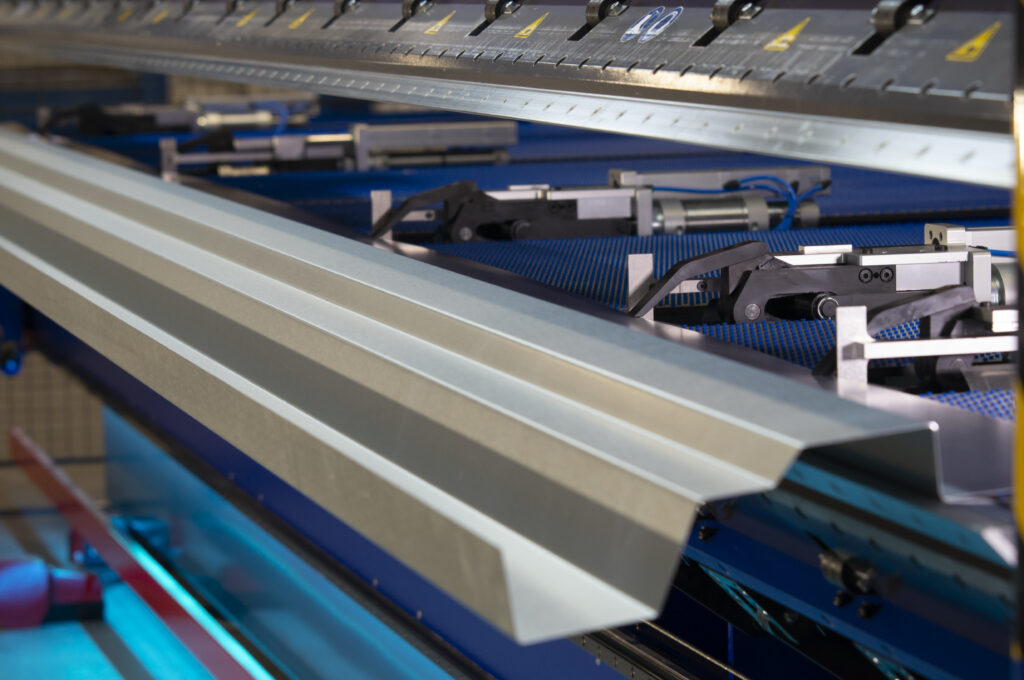

As more and more people know by now, FlexInSheet Kft, or as we call it for short FLINS is not just the developer and producer of the popular Hungarian solar panel supporting structures, but it is also the versatile expert of sheet metal processing in a broader sense – in particular, the specialist of cold-forming of thin sheet metals. During the latter procedure the often surprisingly thin, flexible raw material must be bent in a way that the load-bearing capacity of the final product must be equivalent to the structure of the traditional product made of a raw material of a minimum of 3-mm thickness in a locksmith workshop by welding.

The solution is made possible by the fact that during the bending of thin sheet metals the outer layers are elongated while the inner layers are compressed resulting in the increase of the moment of resistance and rigidity. Thanks to this, elements which meet all engineering expectations can be produced of sheet metals with a thickness of as small as 0.6 mm with multiple cold-bending. By riveting and using them together with a TOX press complex profiles can be made, which can excellently be used for even gridshell hall structures besides simpler structures (e.g. the above-mentioned solar panel supporting structures).

What advantages does the solution optimised by FlexInSheet Kft. have?

It is obvious that if we can achieve the same load-bearing values with the use of significantly less material as compared to traditional technologies with the help of the above-mentioned procedure, this will result in a cost reduction too. Furthermore, the minimised material use – together with the efficient manufacturing technology – will significantly reduce the ecological footprint of metalworking, which becomes a really important factor amidst the increasingly emphasized ESG regulations.

It also arises from raw material saving, that structures made of thin bent sheet metals are regarded as ideal solutions due to their reduced weight, easier transportability or simple installation. Additionally, cold-forming can be robotised very efficiently because of the flexibility and fast, precise workability of the raw material – and high-level automation can also be crucial in the metal industry looking at labour market conditions.

It is not an irrelevant aspect in a number of areas that we can create more aesthetic structures of a higher technical standard from thin sheet metals. Of course, this also means that we have to overcome some real engineering challenges during the design and the production, that is to say we cannot ’save’ thinking – which makes the technology specifically attractive for the team of FlexInSheet Kft. which is always open to tasks requiring complex problem-solving.

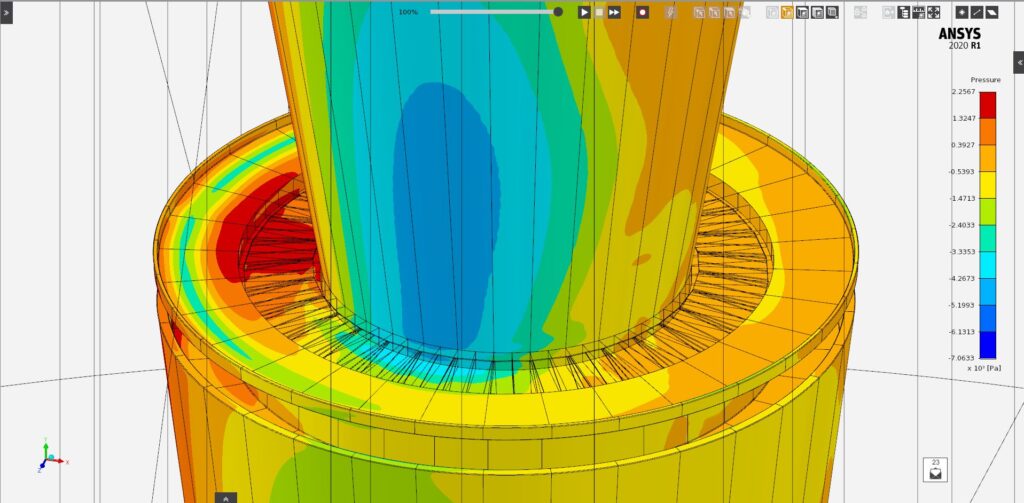

The challenges include the fact that thin, cold-formed profiles may lose their stability in many ways as compared to hot-rolled thicker sheet metals, which must be taken into account from the first moment. Therefore, the experts of FLINS use modern 3D modelling and statistical types of software with which effects expected under real world conditions can be simulated correctly, thus decisions on the exact implementation can be made in light of the results and the necessary load-bearing capacity.It turns out from the fully available article on GyártásTrend portal further to the above, in which areas of use FlexInSheet Kft. does an advanced research and development work in connection with thin sheet metals.